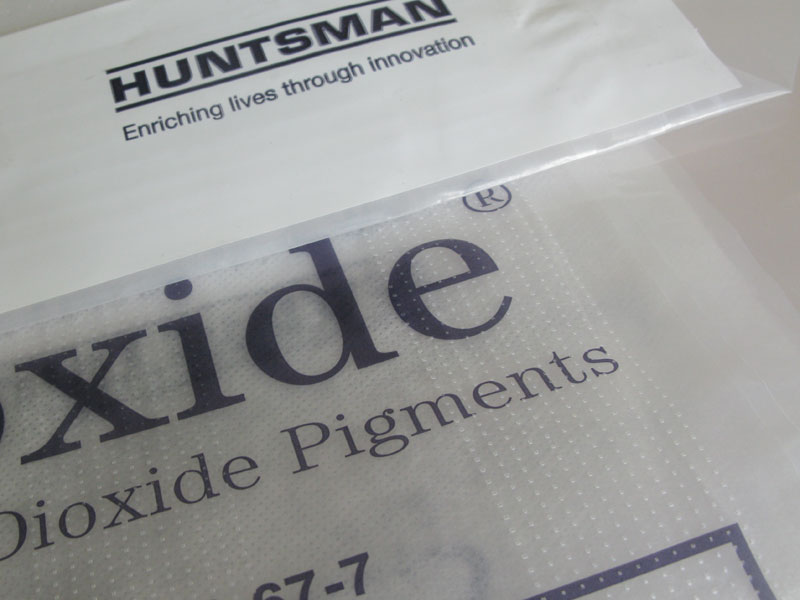

Product: Quick de-aeration PE filter valve sacks

The Huntsman’s Pigments business is a leading global producer of TiO2 pigments and has been manufacturing for seventy five years. The Pigments Division is an international business employing around 2,000 people at facilities in seven countries with a combined total manufacturing capacity of approximately 560,000 tonnes of TiO2 pigment p/a.