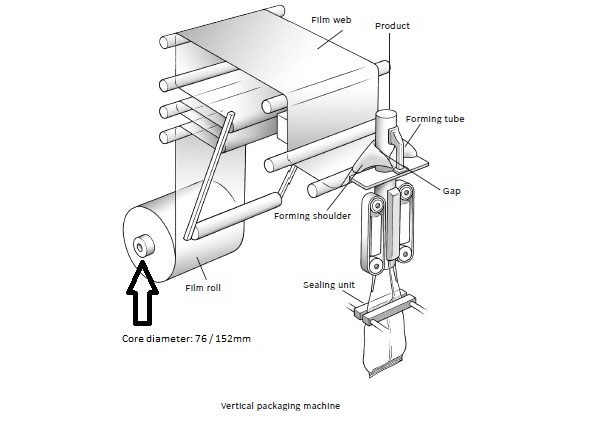

Part 3 of 4 in our vFFS machinery series aims to explain the final product you get from the procedure. Now that we’ve discussed, and have a clearer understanding of the processes behind vFFS machinery we can begin to explain the packaging itself.

The vFFS machinery discussed in the prior articles can produce, three basic plastic bag shapes with countless variations on the three basic models.

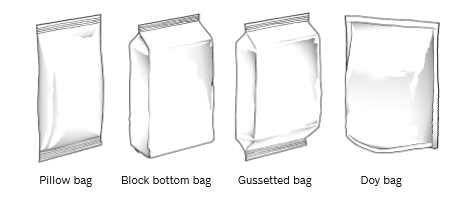

The first basic packaging model is the pillow bag, otherwise known as a flat bag. This is the simplest bag shape and is often used to pack minerals such as sand, compost and peat. To prevent pleats in the cross seams during production, there are bag spreaders located at the bottom of the forming tube.

The gusset bag is a variation on the pillow bag, generally used for packaging within the chemical, pharmaceutical and construction industries to package plastics, polymers and powders. In this model, extra packaging material is folded inwards on both sides. This fold reduces the width of the bag, but also gives it an added depth during filling.

Finally the block bottom bag, otherwise known as a stand-up bag is primarily used for packaging within the food industry for a variety of foodstuffs. A variation of the gusset bag, a mouthpiece is attached at the bottom of the forming tube, this extends from the round shape of the forming tube to the rectangular form of the bottom of the block bottom bag.

As mentioned previously there are countless variations on the three basic models stated above, some examples include corner seal and quad seal bags. Another variant is the doy bag, which is sealed on 3 sides with a block bottom. The three aforementioned are generally smaller packages and are often laminated to give print protection, high gloss and good rigidity. All three often pack a wide range of produce including chemicals, pharmaceutical grade goods, foodstuffs and pet foods.

In the next article we’ll look at the main points in forming, packing and sealing the film for optimum output and best presentation on the pallet to your customers.

As always feel free to get in touch with our team on 01206 266850 or via email at sales@rosenflex.com if you have any queries about plastic sacks or any of our packaging products.